Yinrui Intelligent Releases Safety Operation Guidelines for Glass Processing Line Equipment — Strengthening the First Line of Defense in Production Safety

Safe production remains the cornerstone of manufacturing. For glass processing enterprises, standardized equipment operation is essential for maintaining both safety and efficiency. To help customers operate Yinrui Intelligent’s line equipment safely and efficiently, the company has officially released its Safety Operation Guidelines for Line Equipment. The guidelines cover multiple equipment types—including raw glass storage systems, loading tables, laser marking/cutting machines—and establish clear operating protocols to safeguard customer production safety.

1. During raw glass storage operations, personnel are strictly prohibited from entering the trolley’s operational zone. In the event of any abnormality, press the emergency stop switch and disengage the safety door lock. Only after confirming that no personnel remain in the area may system operations resume. During loading table operation, personnel must maintain safe distance from the equipment; abnormal situations should likewise be addressed using the emergency stop switch. Fine-tuning operations are strictly prohibited on the equipment during maintenance.

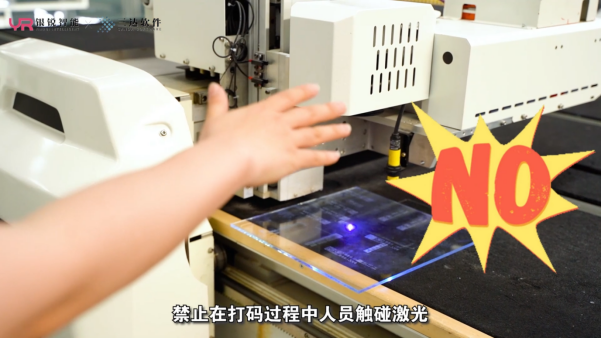

2. During machine operation and marking, personnel must not approach. For abnormal conditions, press the emergency stop switch; for maintenance, switch off the main power supply. When transfer line equipment is running, personnel must not approach or touch belts or rollers. In abnormal situations, activate the main control emergency stop; for maintenance, disconnect the main power.

3. During operation or within the turning range of horizontal-to-vertical equipment, personnel must not approach. For abnormalities, press the emergency stop; for maintenance, level the equipment and switch off the main power. While the vertical rotary table is in operation, personnel must maintain clearance; no personnel or objects shall be permitted within the working radius. For abnormalities, press the emergency stop, and restart only after confirming the area is clear and safe.

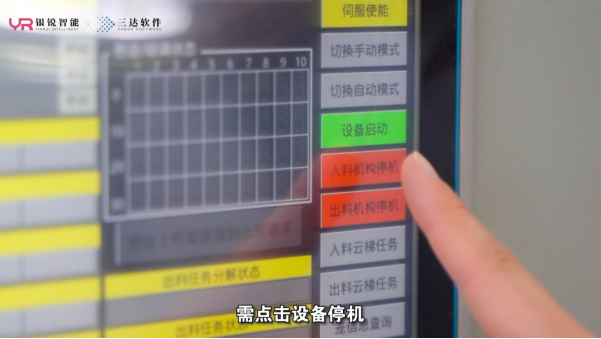

4. When 35-layer sorting equipment is operating, personnel must not approach and must never pass beneath the lifting ladder under any circumstances. In the event of abnormalities, stop the machine, switch to manual mode, and press the emergency stop; for maintenance, switch off the main power. For vertical sorting equipment, personnel must not approach; no personnel or objects shall be permitted in the AGV/RGV trolley operational zone. For abnormalities, press the emergency stop, unlock the safety door, and restart only after confirming complete area clearance.

Yinrui Intelligent always prioritizes customer production safety above all else. These newly released Safety Operation Guidelines provide a comprehensive and clear set of protocols for operating various line equipment. Customers are strongly advised to strictly adhere to these protocols, ensuring every operation meets safety standards. By upholding the principle of “Safe operations, safety for all,” manufacturers can achieve efficient production while maintaining the highest safety standards.

Keywords:

Safety Operation Guidelines for Line Equipment

Safety Operation for Storage System