Smart Factory Solution Cuts Glass Production Downtime to Under 8 Hours Monthly

Yinrui’s Integrated ERP/MES System Sets New Benchmark for Digital Transformation in Glass Manufacturing

Looking to reduce unplanned downtime in your glass factory and boost overall equipment effectiveness? Discover how digital transformation in glass manufacturing is being redefined by Yinrui’s next-generation ERP/MES platform. This smart, fully integrated system is purpose-built to meet the needs of modern glass manufacturers seeking to increase OEE and streamline operations through an advanced glass manufacturing ERP/MES system.

June 25, 2025

Anhui Yinrui Intelligent Technology Co., Ltd has enabled major Chinese glass manufacturers to reduce unplanned downtime to record lows of 5–8 hours monthly. Its integrated glass manufacturing ERP/MES system automates production workflows from raw material storage through tempering and insulating processes, establishing a new standard for digital transformation in glass manufacturing.

Technical Core: Software-Defined Manufacturing

As the central nervous system of the smart factory, Yinrui’s self-developed ERP/MES platform delivers three transformative operational advantages:

1. End-to-End Precision Control

The system establishes real-time connectivity between all critical equipment, including cutting machines, tempering furnaces, and insulating lines, enabling fully automated task scheduling that eliminates inter-process data barriers. This integrated control achieves 40% higher OEE (overall equipment effectiveness),helping customers increase OEE in glass manufacturing significantly over traditional systems.

2. Order-Production Synchronization

The ERP system translates customer orders into production instructions while the MES dynamically optimizes line assignments. This synchronization shortens order fulfillment cycles by 30%, with full progress visibility through unified PC and mobile devices.

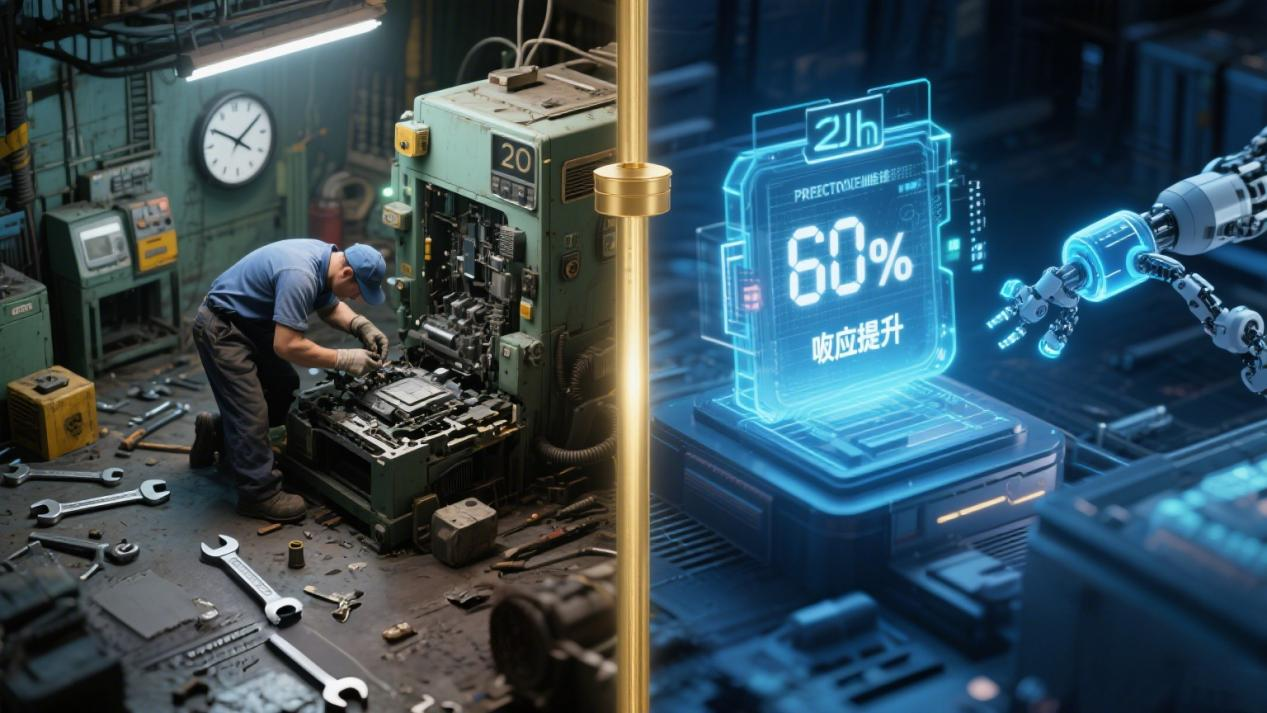

3. Proactive Smart Maintenance

The system continuously analyzes equipment performance data through embedded sensors and AI algorithms. This predictive capability reduces maintenance response times by 60% while helping to reduce unplanned downtime in glass factory operations.

“Managers now have full operational control at their fingertips,” said the CTO of Anhui Yinrui. “Our integrated data visualization system eliminates manufacturing blind spots and facilitates truly demand-driven production flexibility.”

Industry Impact: Digital Transformation Benchmark

This method establishes a new standard for fully integrated digital production in glass manufacturing. Compared to traditional manual inspection and paper-based workflows, the client now delivers unprecedented operational performance:

– 100% data accuracy

– Over 92% equipment utilization

– ≤8-hour monthly unplanned downtime (industry average: 30-50 hours)

About Anhui Yinrui Intelligent Technology Co., Ltd.

Founded in 2005 and headquartered in Anhui, China, Yinrui Intelligent Technology is a nationally recognized innovator in glass manufacturing ERP/MES system integration. We specialize in intelligent equipment and digital solutions for glass processing, including precision cutting machines, automated production lines, and smart factory platforms that help global manufacturers increase OEE in glass manufacturing and reduce unplanned downtime in glass factory operations through end-to-end digital transformation.

Resource Links

Company website: www.yinruigroup.com

Keywords: glass manufacturing ERP/MES system,digital transformation in glass manufacturing, increase OEE in glass manufacturing,reduce unplanned downtime in glass factory