[One-stop turnkey project successfully accepted] Weifang Guanghua Glass System Window Smart Factory

Introduction:

The turnkey project of Weifang Guanghua Glass System Windows Smart Factory has been successfully completed and accepted. This important milestone marks that Weifang Guanghua Glass has made substantial progress in its in-depth layout in the field of intelligent manufacturing, and indicates that it will occupy a more advantageous position in future market competition.

Profil de l'entreprise

Weifang Guanghua Glass, as an expert in the R&D, production and sales of high-quality system windows and glass products, has won wide acclaim in the market for its exquisite craftsmanship, excellent quality and high-quality services over the years. Facing the wave of intelligence, the company actively transforms and is committed to building an efficient and intelligent production system.

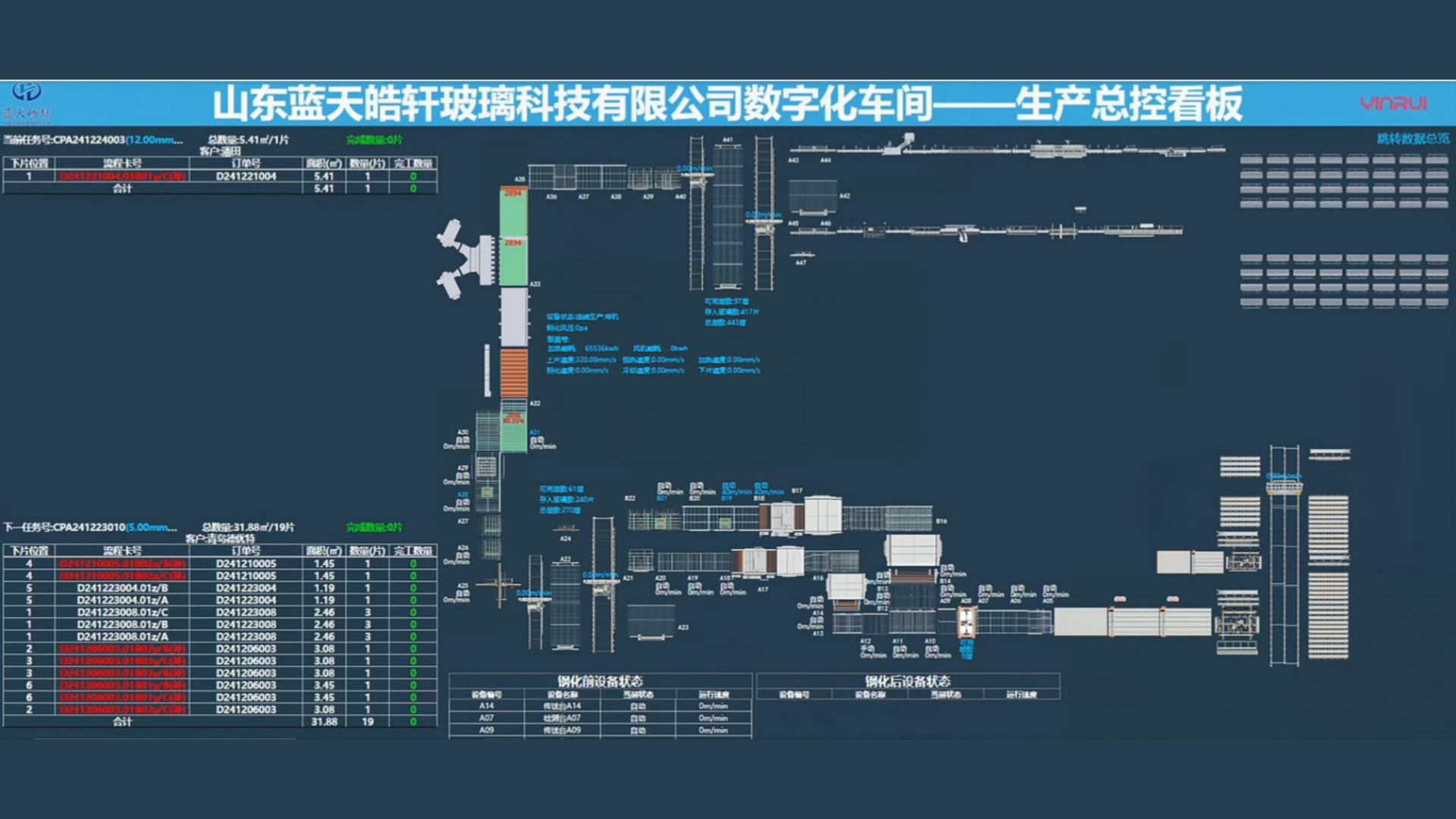

Smart Factory Overview:

The smart factory covers an area of 30,000 square meters, of which the connection equipment area covers an area of 6,000 square meters. It adopts the advanced connection method of “One cutting,two grinding,one tempering and two IGU line”, and only 9 operators are needed to operate efficiently. The factory has a strong ability to handle orders which has many different kinds of sizes, and the glass production size can reach 6000*2850mm. The daily production capacity is as high as 500 square meters of insulated glass, which fully responds to market demand.

Core advantages

Software Highlights

The MES system seamlessly connects to the customer’s ERP to achieve rapid transmission of order data and improve production efficiency.

Lean management, permanent storage and analysis of production data, support for production optimization.

Collect and analyze quality data in real time to ensure product stability and traceability.

Monitor equipment status in real time to prevent potential problems and ensure production continuity

Cutting and grinding connection hardware

Adopt advanced code reading technology to improve code reading efficiency and accuracy.

The MES system automatically sends instructions to the grinding machine based on the code reading information to reduce production errors.

Grinding and tempering Connection Hardware

Code reading technology is used to obtain glass dimensions, enabling efficient transportation and storage.

The vertical sorting solution increases storage capacity and improves loading rate.

The tempered layout algorithm automatically schedules glass according to order requirements to ensure production flexibility.

Tempering and IGU line connection hardware:

The MES system automatically dispatches glass to the corresponding production line based on orders.

The glass delivery AGV delivers the glass in the order of IGU and matching requirements.

Read the code to verify the information, automatically connect the data and print the finished product label to ensure production quality and efficiency.

Look into the future

The successful acceptance of the smart factory marks that Weifang Guanghua Glass has entered a new stage of intelligent manufacturing. Our company will continue to uphold the spirit of innovation, deepen the application of intelligent manufacturing, and lead the industry trend. We firmly believe that with the joint efforts of all employees, Weifang Guanghua Glass will create more value for customers, contribute more to society, and jointly create a bright future for intelligent manufacturing.

Keywords:

Glass Industry,Sanda ERP,Pairing Optimization,Advanced Algorithms,Data Analysis,Production Efficiency,Process Simplification