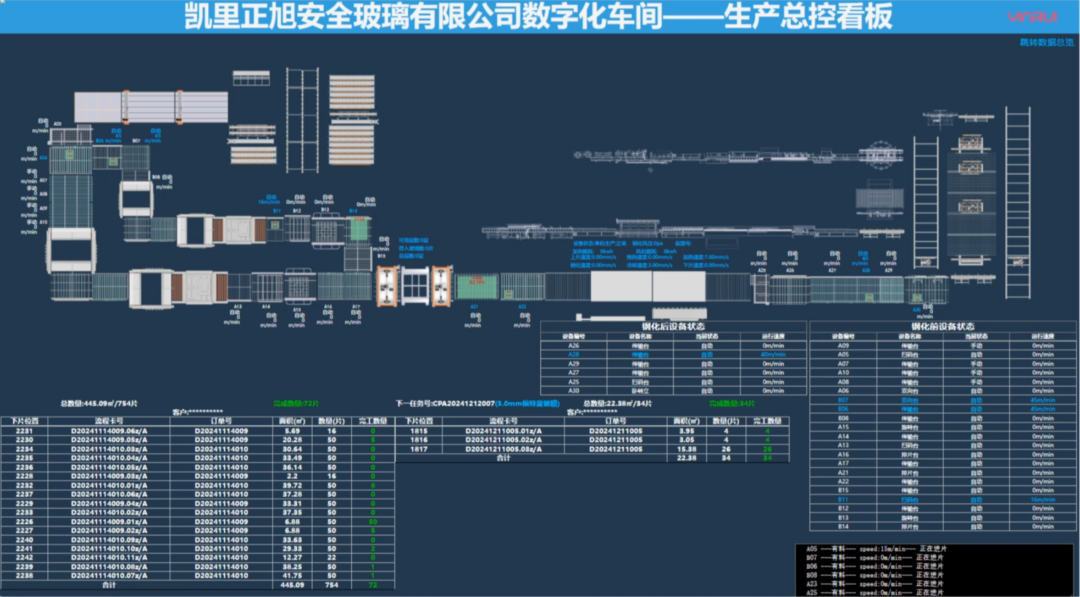

Kaili ZHENGXU Safety Glass: The Shining Star of Guizhou’s First Smart Factory

In Kaili City, Qiandongnan Miao and Dong Autonomous Prefecture, Guizhou Province, a brilliant star is shining brightly – Kaili Zhengxu Safety Glass Co., Ltd., as the first smart factory in the Guizhou region, is leading the industry transformation with a brand-new posture. Today, let’s step into this smart factory for deep processing of door and window glass, meticulously crafted by Yinrui Intelligent, and explore the mysteries and charm behind it.

I. Project Overview

Kaili Zhengxu Safety Glass Co., Ltd. is located in Kaili City, Qiandongnan Miao and Dong Autonomous Prefecture, Guizhou Province, China. It specializes in the production and research and development of system window glass. Its smart factory covers an area of 3,650 square meters and has gathered over 32 elite employees, jointly writing a new chapter of intelligent manufacturing. In September 2024, this smart factory was successfully established, marking Kaili Zhengxu’s official entry into the new era of intelligent manufacturing. Here, high-quality products such as tempered glass and insulating glass are produced, with size ranges from 400mm×350mm to 5000mm×2850mm. The daily output can reach 600 square meters of insulating glass per shift, meeting the diverse demands of the market.

II. Outstanding Features of the Smart Factory

Kaili Zhengxu Smart Factory showcases the boundless charm of intelligent manufacturing with its unique five features:

1. Intelligent Subcontracting, Seamless Production: Through the intelligent subcontracting system, seamless connection of production tasks is achieved, ensuring the continuity and efficiency of the production process.

2. MES-ERP, Automatic Data Flow: The deep integration of MES and ERP systems enables automatic data flow and real-time information sharing, providing strong support for lean management.

3. Data Retention, Lean Management: All production data is fully retained, providing valuable data support for subsequent lean management and continuous improvement.

4. Real-time Quality Inspection, Optimization and Defect Resolution: The introduction of a real-time quality inspection system enables rapid detection and resolution of defects in the production process, ensuring the excellence and stability of product quality.

5. Equipment Monitoring, High Efficiency and Energy Saving: Through the equipment monitoring system, real-time monitoring and efficient management of production equipment are achieved, effectively reducing energy consumption and enhancing production efficiency.

III. Details and Highlights of the Smart Factory:

Entering the Kaili Zhengxu Smart Factory, you will discover more astonishing details and highlights:

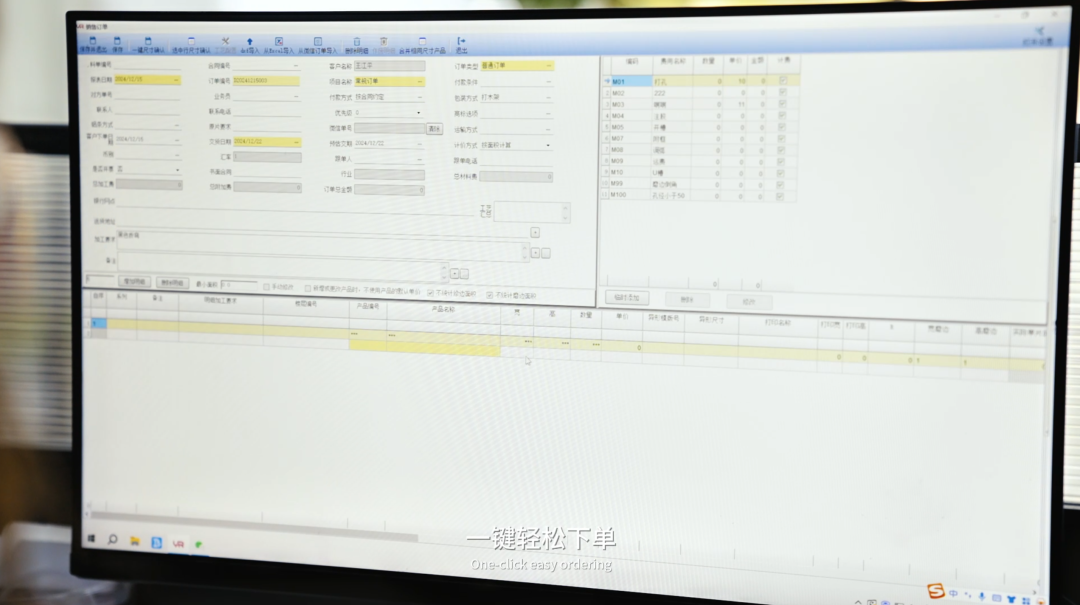

1. One-click Ordering, Convenient and Efficient: Customers can simply place an order with one click to enjoy convenient process configuration services, significantly shortening the production cycle.

2. Intelligent Warehousing, Precise Management: The MES board intelligently analyzes and optimizes the inventory, automatically generating transfer orders based on inventory prompts. The original glass is stored according to instructions, and a usage order is generated as soon as the glass is taken out, achieving precise inventory management.

3. Laser Marking, Permanent Traceability: The laser marking system automatically matches the ERP customer template, allowing multiple logos to be marked on a single original sheet. Each piece of glass has a unique identifier, enabling permanent traceability of production management and finished products.

4. Anthony Cutting, Exquisite Craftsmanship: The Anthony high-end cutting series integrates the unique air knife technology, equipped with precision machine tools and top-tier German equipment, ensuring precise and efficient cutting.

5. Integrated Cutting and Grinding, Intelligent Coordination: As the glass moves, the information is read by the code reader, and the MES system acquires all the information in real time and automatically transmits it to the edge grinding machine. The intelligent control of opening and closing significantly improves production efficiency.

6. Integrated Grinding and Annealing, Optimized Layout: After cleaning, the glass enters the next process through a rotating table. The MES system intelligently decides whether rotation is needed based on layout requirements. The pre-layout uses multi-point cylinder pre-layout technology, effectively promoting the efficiency of the final precise layout. During the sheet extraction stage, the cloud ladder precisely extracts the glass based on the MES annealing layout algorithm and feeds it into the annealing furnace in the center as required by the process.

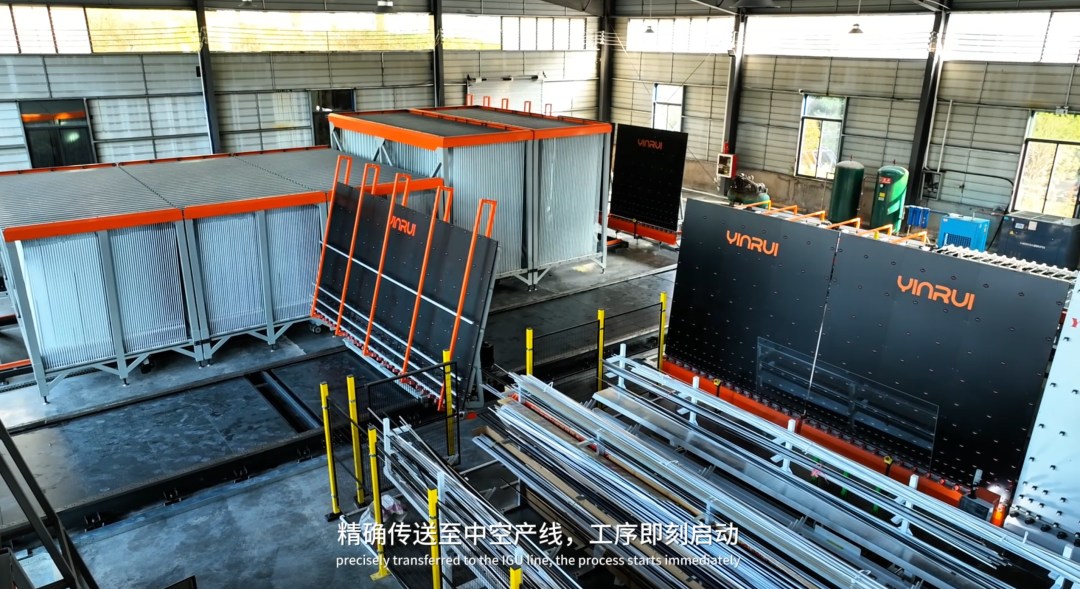

7. Seamless connection in steel production: After scanning and identifying the glass information, the MES algorithm precisely locates the glass loading cage. The glass unloading trolley is accurately conveyed to the insulating glass production line based on the MES scheduling logic, and the process starts immediately. A secondary verification ensures the accuracy of the information, achieving a seamless connection with the insulating glass line. The automated configuration parameters, such as film removal, aluminum frame assembly, and glue depth control, are set accordingly.

Summary: The Brilliant Gem of Smart Manufacturing

The smart factory of Kaili Zhengxu Safety Glass Co., Ltd., with its smooth operation of the fully automated production process, immediate printing of product labels, and detailed record-keeping of information, showcases the boundless potential and charm of smart manufacturing. This smart factory, meticulously crafted by Yinrui Intelligent, not only enhances production efficiency and product quality but also sets a new benchmark for the industry’s future development. Let’s look forward to Kaili Zhengxu’s continued progress on the path of smart manufacturing, contributing more wisdom and strength to the glass manufacturing industry in Guizhou and across the country!

Keywords:

Glass Industry,Sanda ERP,Pairing Optimization,Advanced Algorithms,Data Analysis,Production Efficiency,Process Simplification