Sanda ERP [Unusual Glass, One-click Smart Cutting]

In the glass industry production process, the order-taking stage often involves the processing of a large number of irregular graphic designs. These irregular graphic designs are not only diverse in types, but also often need to be customized according to customer needs. For order-takers without drawing experience, this is undoubtedly a highly challenging task. However, now, Sanda Technology has provided a new solution for the glass industry with its ERP system – irregular graphic library and irregular assembly optimization function.

1. Irregular Shape Library: A New Option for Swift Order Placement

Our ERP system comes with a comprehensive library of irregular shapes, which includes a variety of common irregular shapes. Order takers do not need to have professional drawing skills. They simply need to browse and select the irregular shapes they need from the system, and they can complete the order process. This function not only greatly improves the order-taking efficiency but also reduces the requirement for professional skills of the order takers, making it easier for more people to perform this job.

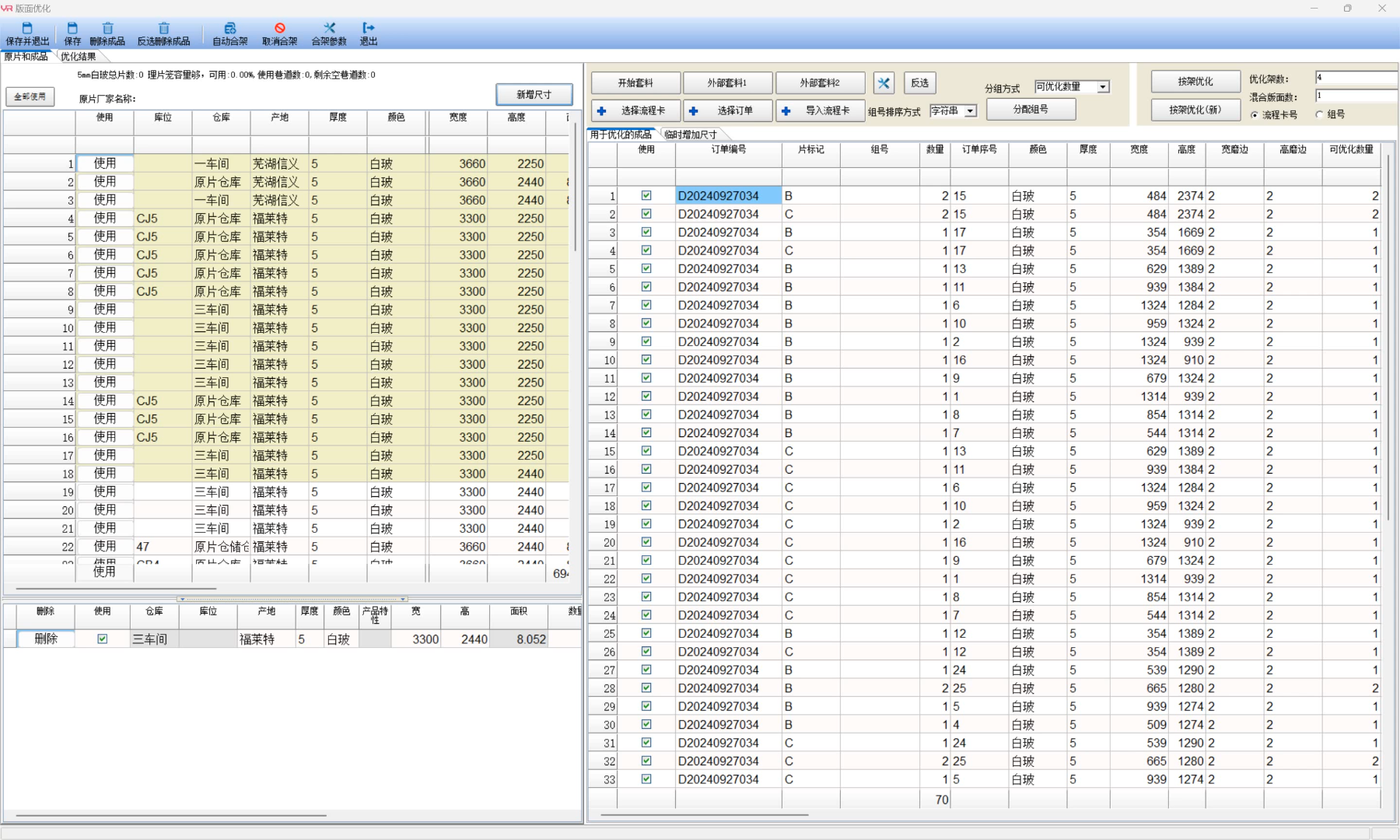

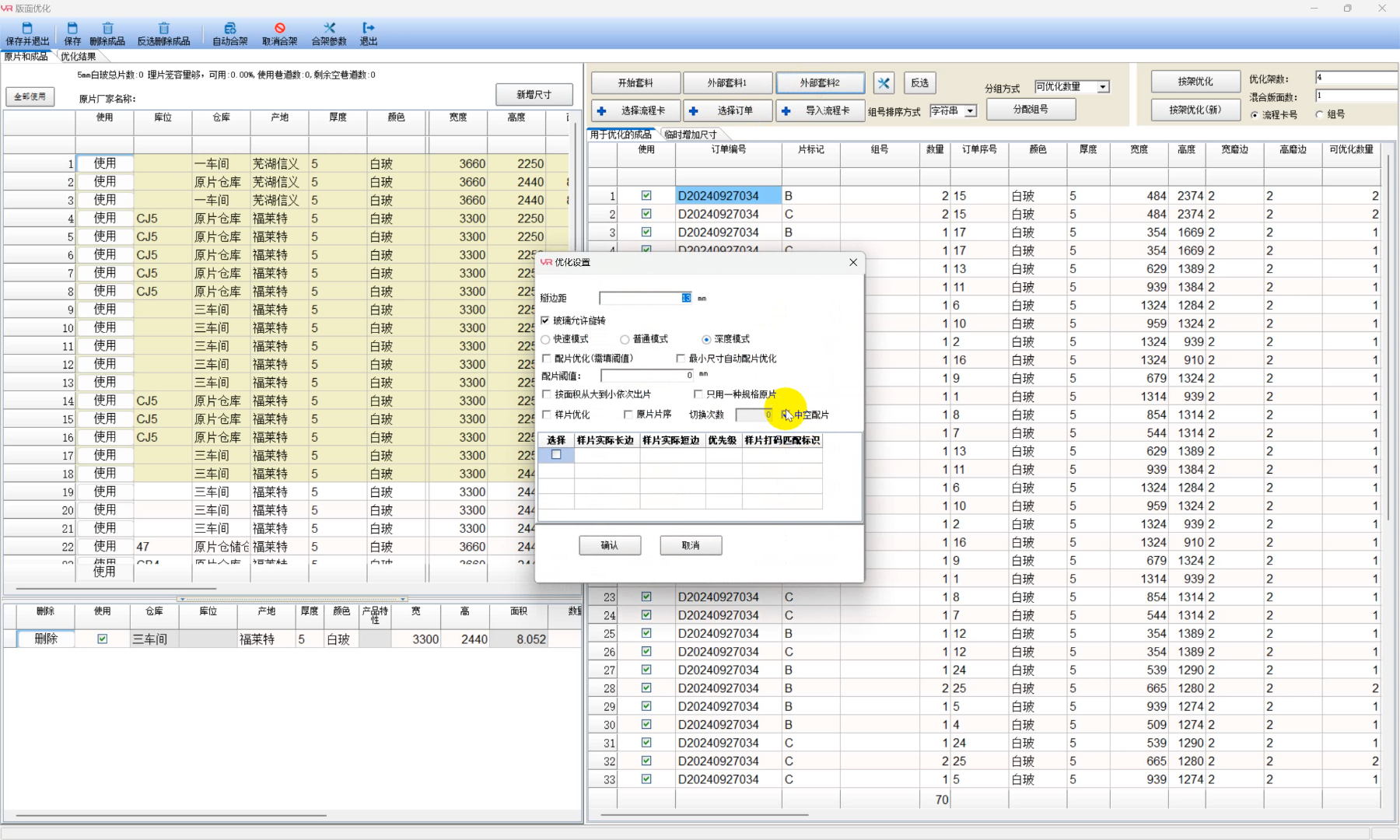

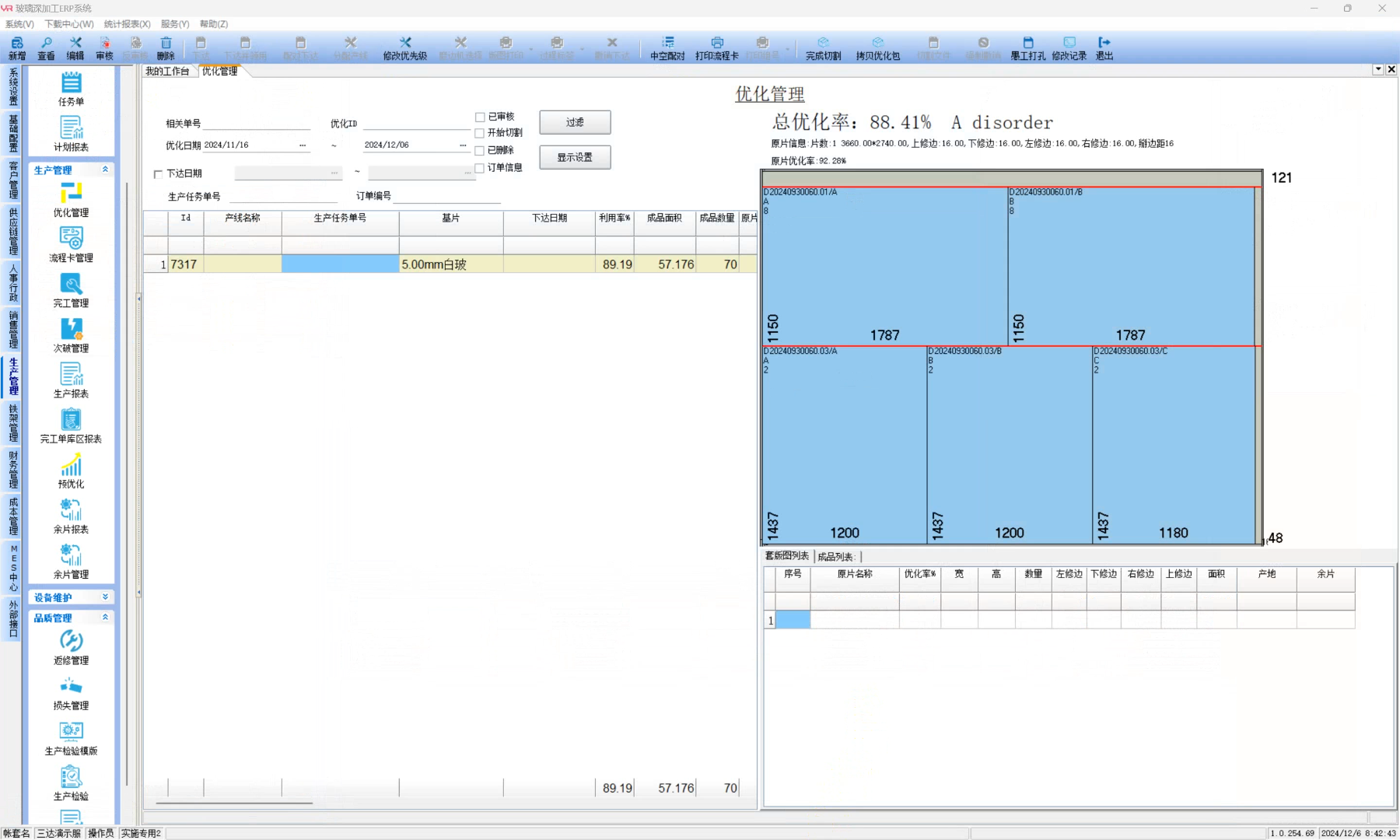

2. Optimize cutting replenish one-click operation, efficient and convenient

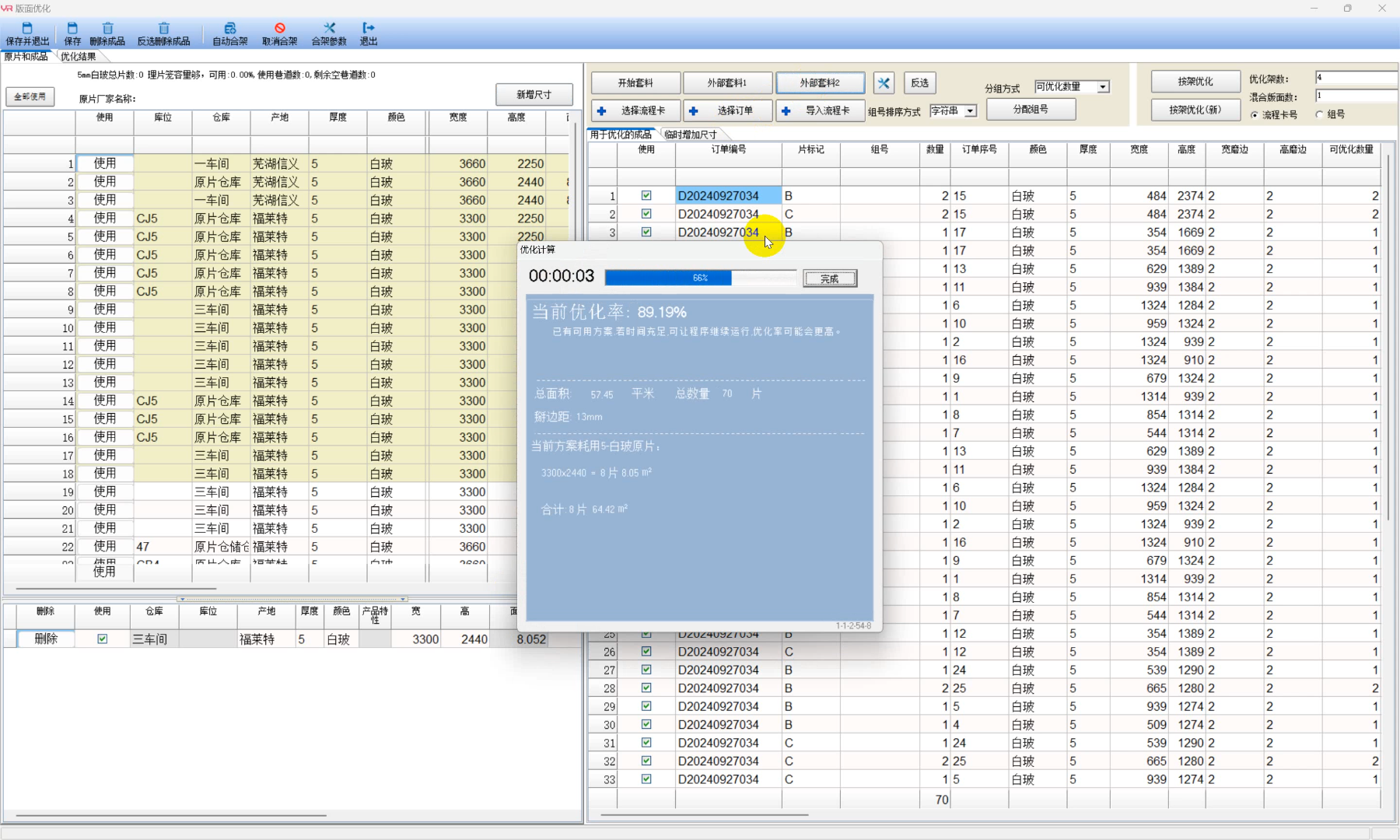

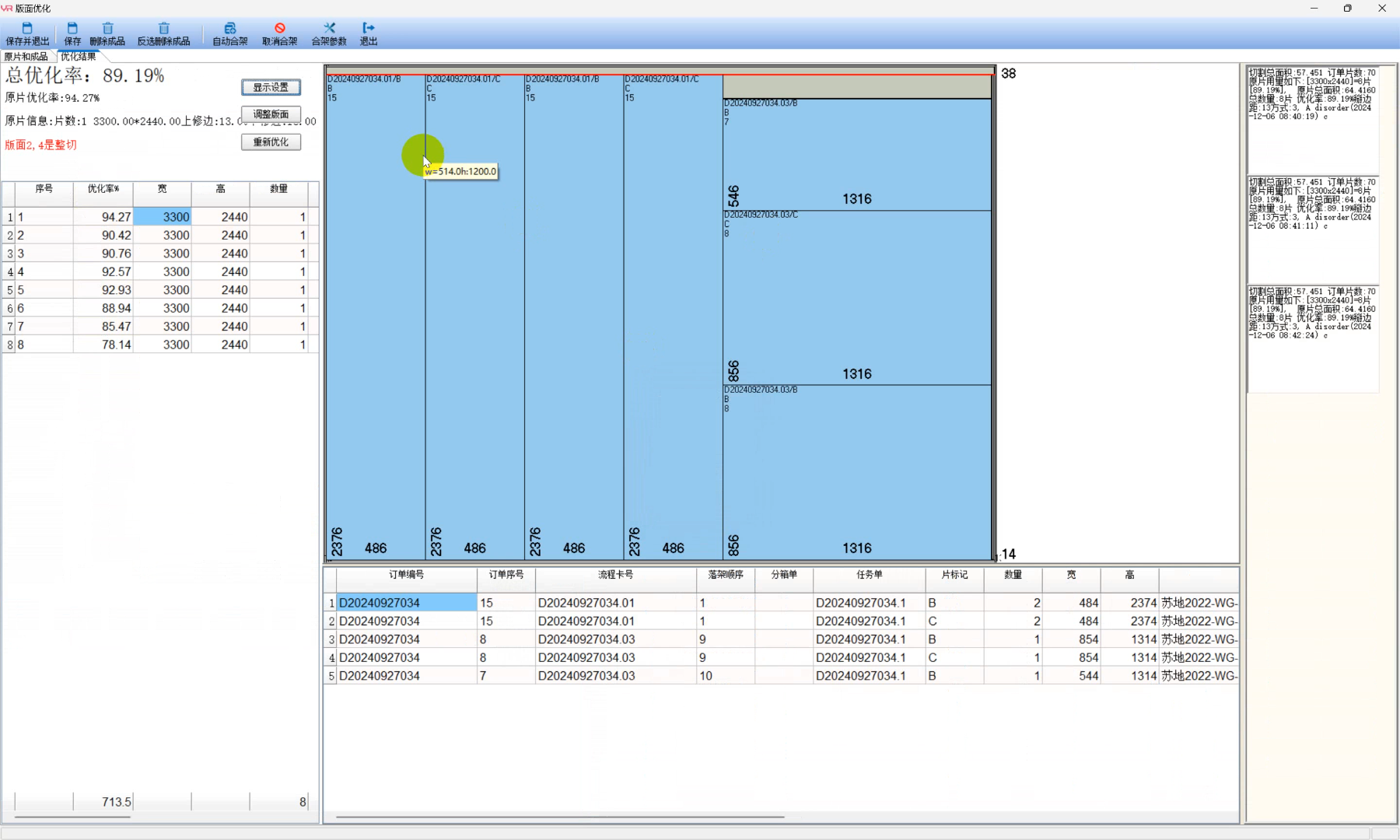

What’s even more surprising is that the graphics in the Alien Library can not only be used directly for ordering, but also optimized and sent directly to the cutting machine for cutting. This feature achieves a seamless transition from ordering to production, greatly improving production efficiency and accuracy. Ordering personnel can simply operate to complete the entire process from graphic selection to cutting instruction issuance, truly achieving “one-click” production.

3. Optimized irregular shape cutting: intelligent cutting, saving material

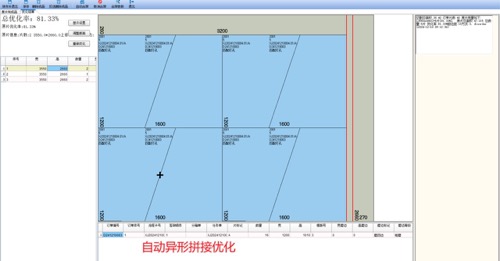

In the glass cutting process, the assembly of irregular graphic patterns is an important step. Traditional assembly methods often require manual labor, which is not only time-consuming and labor-intensive, but also difficult to ensure the accuracy and optimization of the assembly. However, our ERP system uses advanced intelligent assembly optimization algorithms to automatically optimize the assembly of irregular graphic patterns that can be assembled. This function not only greatly improves the accuracy and efficiency of the assembly, but also effectively saves material and reduces production costs.

4. Conclusion

Sanda Technology’s ERP system for the glass industry, by introducing irregular shape libraries and optimizing irregular shape assembly functions, successfully solved the problem of insufficient drawing experience and low production efficiency for order takers. This innovative solution not only improved production efficiency and reduced production costs, but also injected new vitality into the digital transformation of the glass industry. We believe that in the future, Sanda Technology will continue to lead the digital transformation trend in the glass industry and bring more efficient and intelligent production solutions to more enterprises.

Follow us to learn more about the latest developments and cutting-edge features of ERP systems for the glass industry!

Keywords:

1.Glass Industry 2. Sanda ERP 3. Pairing Optimization 4. Advanced Algorithms