Anthony High-End Series: Defining a Benchmark for Smart Glass Deep Processing

In the global wave of digital transformation, high-efficiency collaboration and stable output have become critical for glass manufacturers to overcome growth bottlenecks. Yinrui Intelligent’s Anthony high precision glass cutting machine for smart factories combines robust technology, innovative design, and intelligent adaptability. More than just a piece of equipment, it is a driving force enabling the industry to leap from traditional processing to intelligent manufacturing.

Solid Technology: Built on German Standards

The core competitiveness of the Anthony series comes from deep technical refinement focused on long-term stability and ultimate efficiency.

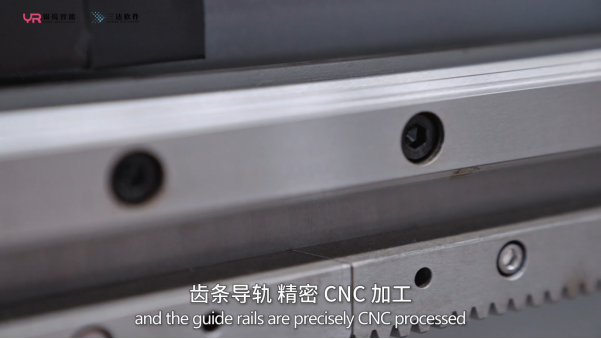

- Advanced CNC glass cutting system with German standards: Using BECKHOFF control systems, premium steel welded frames, and stress-relieving processes, the equipment eliminates deformation risks in 24/7 operation. Precision CNC machining of rack rails ensures zero vibration or drift, making it ideal for continuous production of high-end glass such as automotive safety glass and photovoltaic ultra-clear glass.

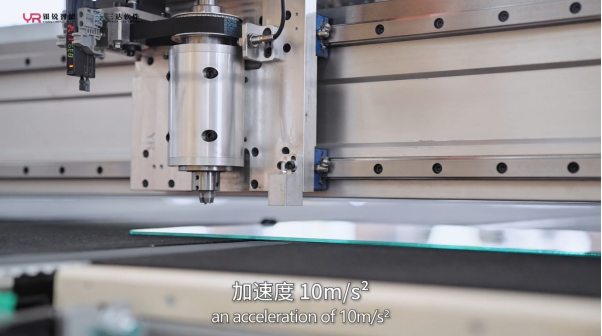

- Speed and accuracy combined: With a dual-drive gantry structure, speeds of 220m/min, and acceleration above 10m/s², paired with patented cutting blades, the system achieves efficiency gains of over 20% while maintaining ±0.15mm precision, even on ultra-thick 19mm glass.

Functional Innovation: Integration and Flexibility

The Anthony series also redefines workflows with its integrated glass processing equipment with multi-function design.

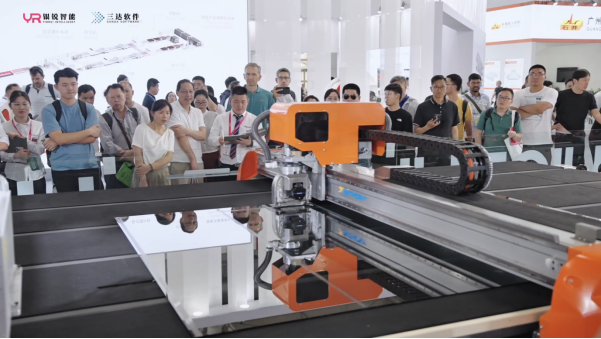

- Dual-beam structure: Launched at the 2025 Beijing Glass Exhibition, this design delivers high throughput within a small footprint—saving over 40% of workshop space without compromising 200m/min speed or precision.

- Two-in-one and three-in-one integration: Laser marking + cutting, or laser marking + film removal + cutting, condenses three processes into one machine, reshaping efficiency for space-constrained factories in urban cores.

Intelligent Adaptation: Full Digital Transformation

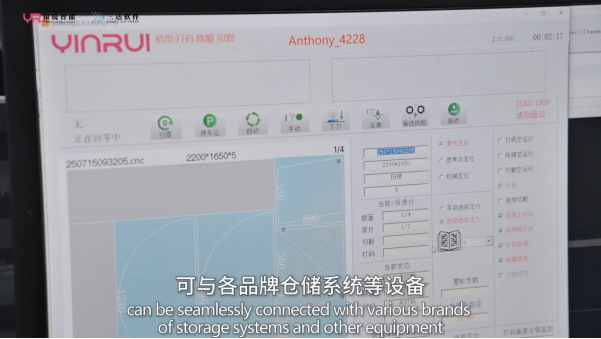

Beyond machinery, the Anthony series acts as a digital hub for the smart factory.

- Its software and hardware integrate seamlessly with Siemens and Fanuc systems and connect directly with ERP and MES platforms. Real-time data—including cutting precision and blade wear—are visualized across the full production chain. This is exactly what global manufacturers demand from digital transformation solutions in glass deep processing.

- Proven in global deployments, Anthony adapts to diverse scenarios: small-batch customization in European home glass, high-volume precision in Southeast Asian automotive glass, and continuous production in Chinese photovoltaic glass.

By delivering long-term stability, speed, and precision, Anthony helps manufacturers maximize efficiency in glass manufacturing lines. It represents not only a high-efficiency solution but also a benchmark defining the future of smart, high-end glass processing worldwide.

Key words: