أصدرت شركة Yinrui للابتكار الذكي نظام فحص بصري تخريبي للمساعدة في ترقية صناعة المعالجة العميقة للزجاج

Traditional production enterprises use the human eye to detect defects, but this method has the disadvantages of high cost, easy fatigue, slow speed, etc., and has great instability and non-standard, which cannot meet the needs of high-quality production process.

In order to cope with these problems, machine vision is gradually replacing the human eye for intelligent image acquisition and processing, realizing accurate detection, intelligent classification and grading of defects, reducing labor costs and improving production efficiency.

01/

Distinguish performance and reputation

Choose a quality solution

Nowadays, although visual inspection systems are springing up, there are also good and bad situations, and it is necessary to carefully distinguish their performance and reputation when choosing. Once an inferior detection system is selected, it will not only fail to improve production efficiency, but also affect the production progress and reputation of the enterprise.

As early as 2019, Yinrui Intelligent began to invest in the research and development of an intelligent defect detection system for glass deep processing based on machine vision, which integrates deep learning technology and can comprehensively and quickly detect glass surface defects in continuous operation online or offline.

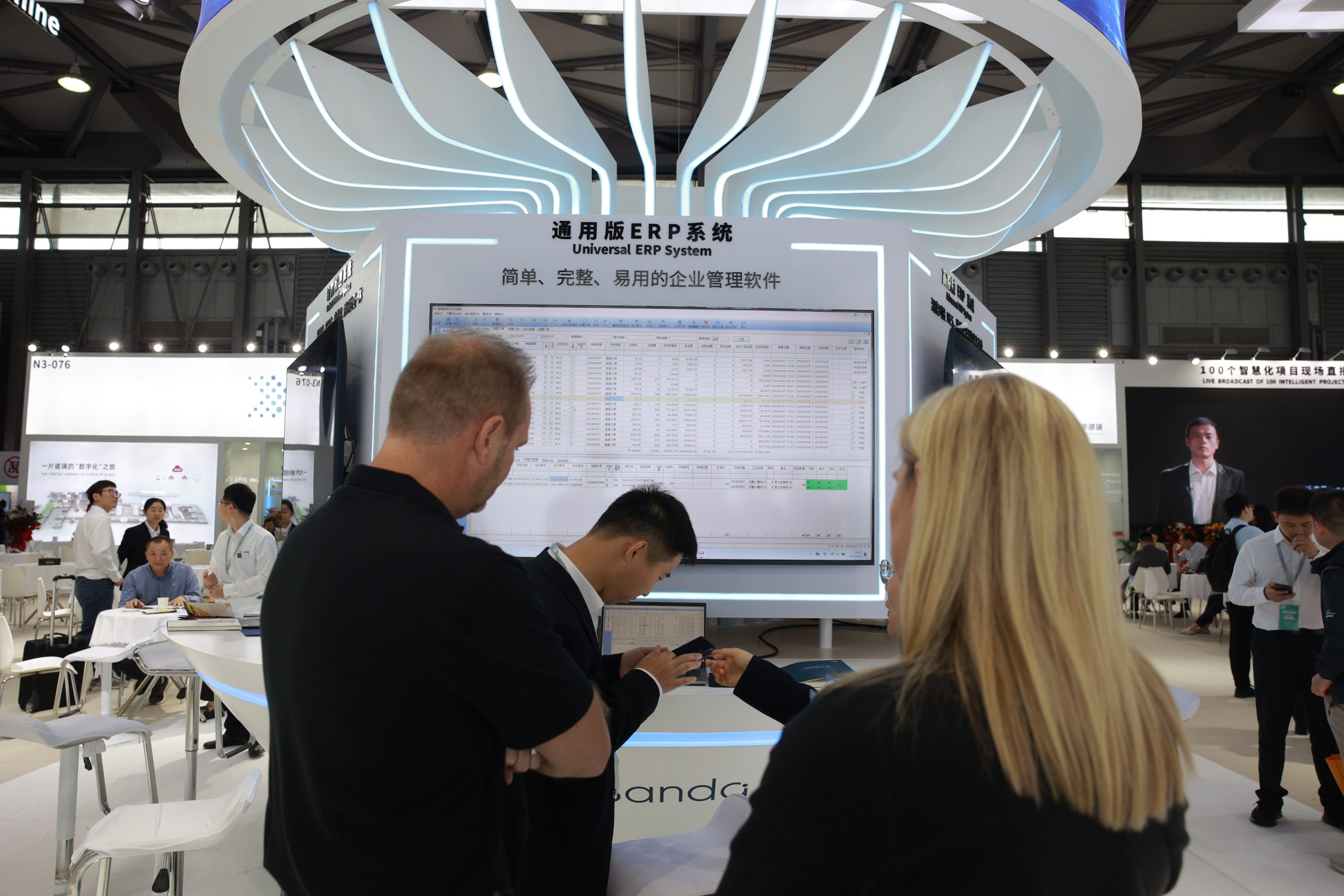

For float glass, flat glass, display glass, coated glass, and architectural glass produced by glass deep processing enterprises, its modular design can detect defects such as black spots, bubbles, missing corners, water droplets, and decoating in real time, and communicate with MES/ERP real-time data, automatically summarize and analyze quality information, and provide effective solutions for enterprises to ensure product quality.

02/

Abundant cooperation cases and good reputation

Verify the professionalism of the system

Once the defect detection system was launched, it has reached cooperation with 13 companies, including Foshan Yixin Glass Technology Co., Ltd., Xinhaoxuan Technology (Xinxing) Co., Ltd., Guangdong Guanda New Material Technology Co., Ltd., and Henan Shengguo Glass Co., Ltd., and has won a good reputation.

Foshan Yixin Glass Technology Co., Ltd. successfully applied the system in 2023 and is full of praise for its results. The person in charge of Yixin Glass said: “Yinrui Intelligent’s visual defect detection system has greatly improved our production efficiency and product quality, reduced the cost and error of manual inspection, and is our right-hand man in the process of intelligent transformation.”

03/

Technical strength and team strength

Escort new product launches

The strong software and hardware strength and the support of the technical R&D team provide a strong confidence for Yinrui Intelligent to release a new visual defect detection system. As the leader and enabler of the intelligent transformation of enterprises in the glass industry, Yinrui Intelligent firmly grasped the industry vane in 2015, fully opened industrial intelligence, and moved from a stand-alone device to an intelligent connection solution provider.

In terms of software development, Yinrui Intelligent Software Team has more than 60 software and electrical engineers, and the core developers are software designers and system architects with more than 10 to 15 years of development experience.

All in all, the visual defect detection system for glass deep processing launched by Yinrui Intelligent is of great significance for the intelligent transformation of glass deep processing enterprises. It is believed that more enterprises will adopt this system in the future to achieve intelligent transformation.